1

/

of

1

PROTEC GAS

Flowmeter is equipped with a passive generator of the frequency-pulse signal.

Flowmeter is equipped with a passive generator of the frequency-pulse signal.

Regular price

$1,200.00

Regular price

Sale price

$1,200.00

Unit price

/

per

Couldn't load pickup availability

Reference Turbine Gas Meters EFS-T are intended for installation on reference calibration rigs for calibration and verification of gas meters of any type with air as operating environment. The meters are equipped with electronics unit (EU) and rotary transducer with mounted binary pulse-frequency sensors and pressure sensors.

The meter EFS-T is intended for measuring the volume of gas passing through its input channel of circular section. The gas flow volume is transmitted to a PC via the EU. The meters are designed for vertical installation on the reference equipment with DN 50 mm, DN 80 mm, DN 100 mm, DN 150 mm, DN 200 mm, DN 250 mm, DN 300 mm, DN 400 mm.

Connection between the meter and PC is carried out via RS-485. Exchange protocol - ModBus RTU. “Start-stop” synchronization is of two-wire type based on the communication line RS-485.

TABLE -1

| DN | Standard size | Qmax, m 3 /h | Qmin, m 3 /h |

|---|---|---|---|

| 400 | G6500 | 10000 | 500 |

| 400 | G4000 | 6500 | 325 |

| 300 | G4000 | 6500 | 325 |

| 250 | G2500 | 4000 | 200 |

| 200 | G1600 | 2500 | 125 |

| 150 | G1000 | 1600 | 80 |

| 100 | G400 | 650 | 35 |

| 80 | G250 | 400 | 20 |

| 50 | G100 | 160 | 8 |

TABLE - 2

| Parameters | Value | |

|---|---|---|

| General industrial application design | Explosion-proof design | |

| Measuring medium | air | |

| Operating pressure, MPa | 1,6; 4,0; 6,3 | |

| Limits of basic relative permissible error, not worse % |

± 0,2 | |

| Repetition, at least % | ± 0,03 | |

| Repeating accuracy within 2 years, at least % | ± 0,1 | |

| Frequency output with adjusted multiplication factor Fmax, kHz | 5 | |

| Signal of flow rate excess for the emergency system shutdown | Type «dry contact» | |

| Loading capacitance of emergency output shutdown: voltage, V, max max current, mA, max |

24 20 |

|

| Operating conditions: -Temperature of operating environment and ambient air, °C, at least - Relative humidity of air at temperature +25 °C, % - atmospheric pressure, kPa |

10 up to 30 up to 80 from 84,0 up to 106,7 |

|

| Power consumption, W, max | 0,5 | 6,0 |

| Supply voltage, DCV | from 9 up to 24 | |

| Lifetime, min. years | 10 | |

Archive data:

- hourly- for every preceding hour - size of archive 1488 records (62 days);

- daily- for every preceding day - size of archive 730 records;

- power on/off instances - size of archive 512 messages;

- emergency situations - size of archive 720 messages;

- intervention - changing the adjustment parameters (size of archive 889 messages).

Control software program is used for recording, viewing and changing the settings of the flow meter , recording and viewing of measurement data, as well as for reading data archive.

This program allows you to view the archive data and modify the flow meter settings via a PC monitor and then upload the archive data to a file on the flow meter. The flow meter provides protection of settings and archive data from unauthorized changing by restricting access through a system of passwords and hardware based protection of configuration from being overwritten.

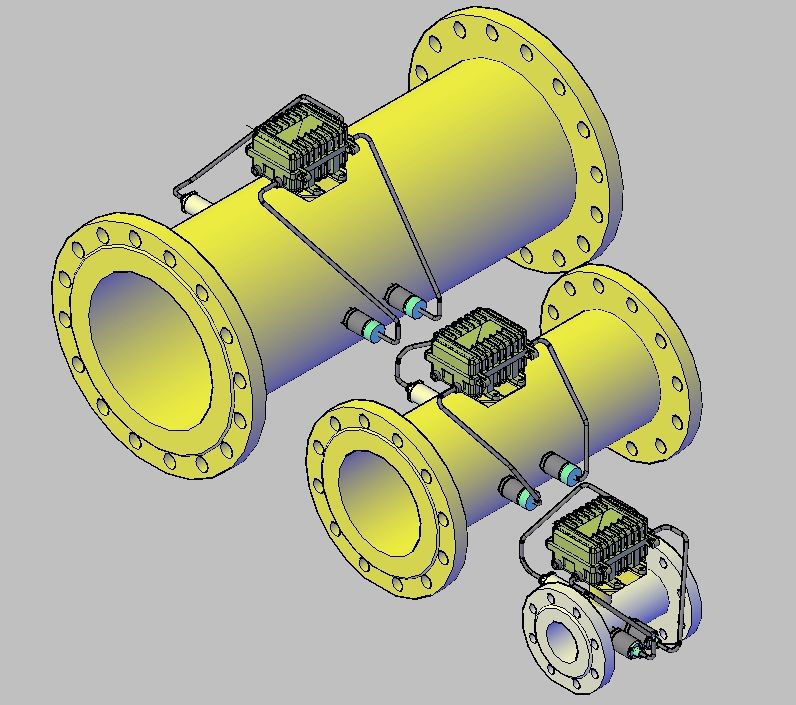

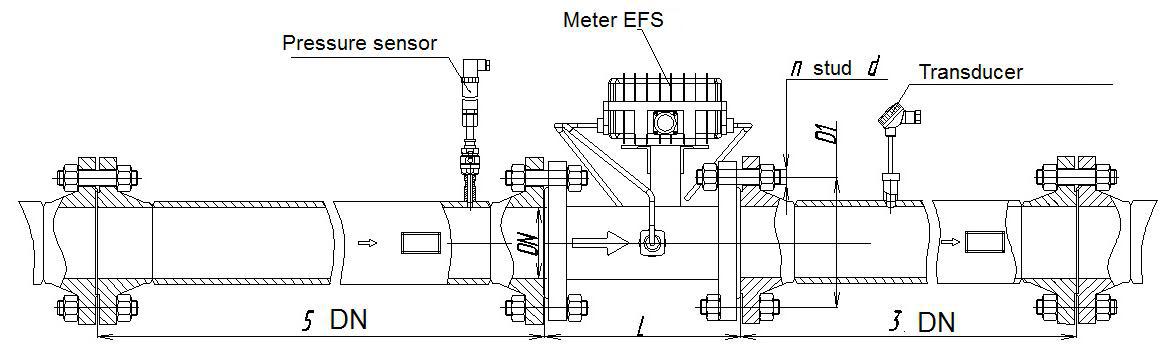

APPENDIX A - General Appearance

Turbine Gas Meters EFS-T

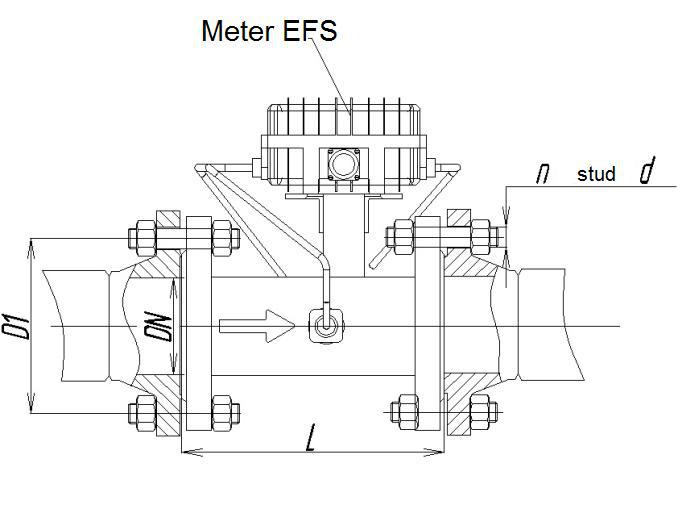

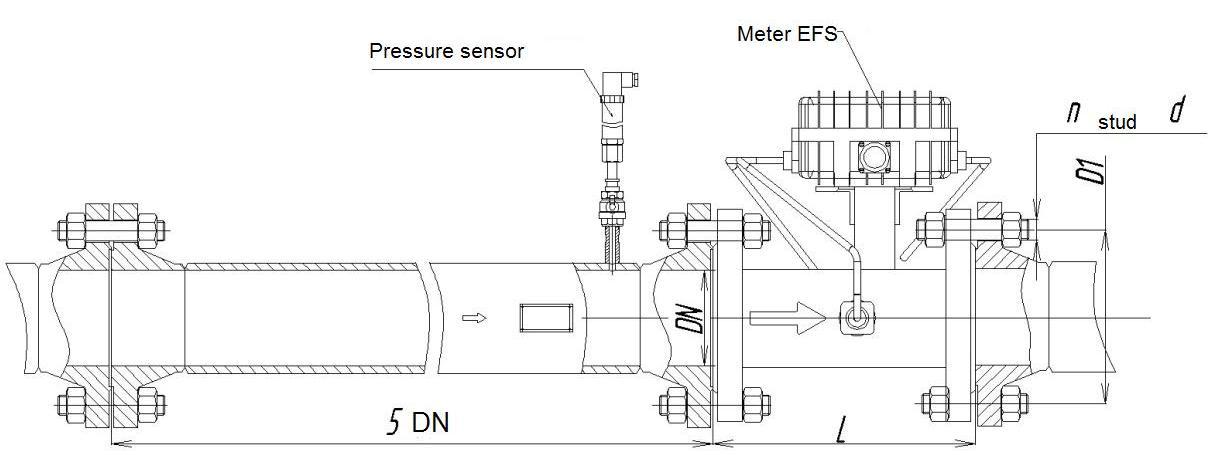

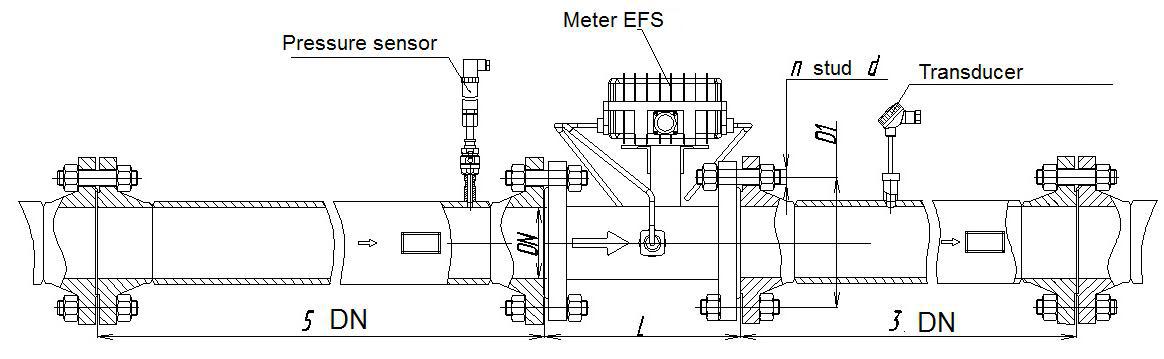

Turbine Gas Meters EFS-TAPPENDIX B - Possible solutions of meter mounting

APPENDIX C -Dimensions of the meter with straight run

TABLE - 3

| DN, mm | Rating, MPa | L, mm | D1, mm | n | d, mm |

|---|---|---|---|---|---|

|

50 |

1,6 |

150 |

125 |

4 |

18 |

| 4,0 | 125 | 16 | |||

| 6,3 | 135 | 22 | |||

|

80 |

1,6 |

240 |

-- |

8 |

18 |

| 4,0 | 160 | 16 | |||

| 6,3 | 170 | 22 | |||

|

100 |

1,6 |

300 |

180 |

8 |

22 |

| 4,0 | 190 |

20 | |||

| 6,3 |

200 | 26 | |||

|

150 |

1,6 |

450 |

240 |

8 |

22 |

| 4,0 | 250 | 24 | |||

| 6,3 |

280 | 33 | |||

|

200 |

1,6 |

600 |

295 |

12 |

22 |

| 4,0 | 320 | 27 | |||

| 6,3 | 345 | 33 | |||

|

250 |

1,6 |

750 |

355 |

12 |

26 |

| 4,0 | 385 | 30 | |||

| 6,3 | 400 | 39 | |||

|

300 |

1,6 |

900 |

410 | 12 | 26 |

| 4,0 | 450 |

16 |

30 | ||

| 6,3 | 460 | 39 | |||

|

400 |

1,6 |

1200 |

580 |

16 |

30 |

| 4,0 | 670 | 42 | |||

| 6,3 | 715 | 48 |

APPENDIX D - Order code for reference turbine

gas meter

gas meter

EPS-T/200/1600/20/0,2/0/0/0/1/1/S

TABLE - 4

| # | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EFS- | T | D | G | N | P | Ak | Sm | Mp | I | Dp | Dt | S |

Legend explanation of typical order codes is given

in Table 4

| # | Elements Legend | Meter's characteristics |

|---|---|---|

| 1 | EFS- | Type of the reference meter. |

| 2 | Т | Type of meter sections: Т - turbine |

| 3 | D | Nominal meter diameter, mm |

| 4 | G | Meter standard size |

| 5 | N | Flow range:20 – 1/20 Qmax, 30 – 1/30 Qmax |

| 6 | P | Absolute operating pressure (1,6; 4,0; 6,3) МPа. |

| 7 | Ak | Meter accuracy: 0,2% |

| 8 | Sm | Counting mechanism: 1 – yes, 0 – no. |

| 9 | Mp | Availability of seal oil pump: 1 – yes, 0 – no. |

| 10 | I | Type and quantity of pulse sensors: 0 – no, 1 – one low-frequency (LF), 2 – one high (HF), 3 – one low-frequency (LF) and one high (HF), 4 – two high (HF), 5 – one low-frequency (LF) and two high (HF). |

| 11 | Dp | Availability of the pressure sensor: 1 – yes, 0 – no. |

| 12 | Dt | Availability of the temperature sensor: 1 – yes, 0 – no. |

| 13 | S | Section material : S- Steel.20, А – stainless steel. |

Share